The Alexandra team are here to help...

Enquire About SiteGard CraneGard

Our experienced staff are always ready to help and share their personal expertise to guide you to the right perimeter security solution.

01892 833 001

or Email: customersupport@alexandrasecurity.com

SiteGard® CraneGard – Tower Crane Protection and Access Control

CraneGard: Trusted Tower Crane Protection and Safety Barrier

CraneGard, part of our trusted SiteGard® range, is a purpose-designed tower crane protection solution that delivers high-performance, wind-tested, anti-climb perimeter security. This robust system forms a clearly defined safety barrier around the base of a tower crane, helping safeguard workers while preventing unauthorised access to the crane mast and structure.

The Growing Risk of Unauthorised Tower Crane Climbing

Across the UK, incidents of unauthorised tower crane climbing are rising — especially after hours. Construction sites are increasingly targeted by thrill-seekers, social media influencers, and protesters, all of whom put themselves and others at extreme risk. These dangerous activities can lead to:

- Serious injury or fatal falls

- Structural damage to the crane

- Costly project delays

- Reputational damage for the contractor

As a result, enhancing tower crane safety with dedicated crane protection barriers is more critical than ever.

Contractor Responsibility for Crane Security and Site Safety

Under UK regulations, the main contractor holds responsibility for ensuring the security and safety of construction sites, including tower crane access control. Adequate protection must be in place to:

- Prevent unauthorised access and climbing

- Enable safe working conditions for erection, dismantling, and maintenance crews

- Minimise wind loading on crane foundations and surrounding structures

Why Wooden Hoarding Falls Short for Crane Safety

While timber hoarding is sometimes used to form a perimeter around crane bases, it presents multiple drawbacks when measured against modern crane safety barrier systems:

- Climbable Surface: Wooden panels can be scaled, compromising security

- Limited Visibility: Hoarding obscures crane bases, complicating safety inspections and reducing natural light

- Wind Load Concerns: Solid hoarding increases wind pressure on posts and ground fixings

- Single-Use Material: Hoarding is rarely reusable, leading to increased costs and waste

- Fire Safety Risks: Timber is flammable and can hinder emergency access

CraneGard – Enhanced Security for Today’s Tower Crane Sites

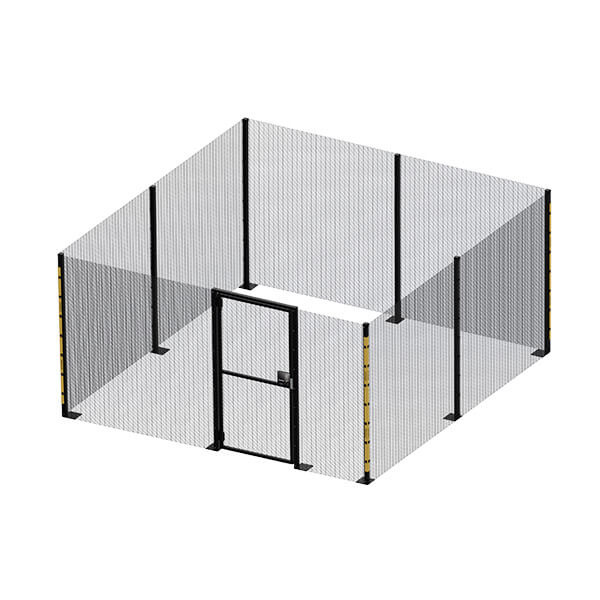

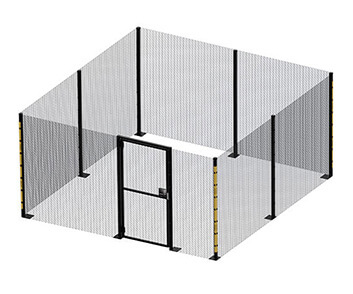

CraneGard is engineered to deliver dependable tower crane base protection and site access control without the limitations of traditional hoarding. This 2.4-metre or 3.0m-high compound features:

- Anti-Climb Design: Made with tight-aperture 358 weld-mesh panels

- Wind-Resistant Construction: Open mesh reduces wind loading while maintaining strength

- 360° Visibility: Enables full visual inspection and monitoring around the crane base

- Powder-Coated Finish: Durable and professional appearance

CraneGard meets key criteria for health and safety compliance on modern construction sites.

Quick to Deploy, Easy to Reuse

Designed with installation efficiency in mind, CraneGard cuts labour time and on-site complexity. Key features include:

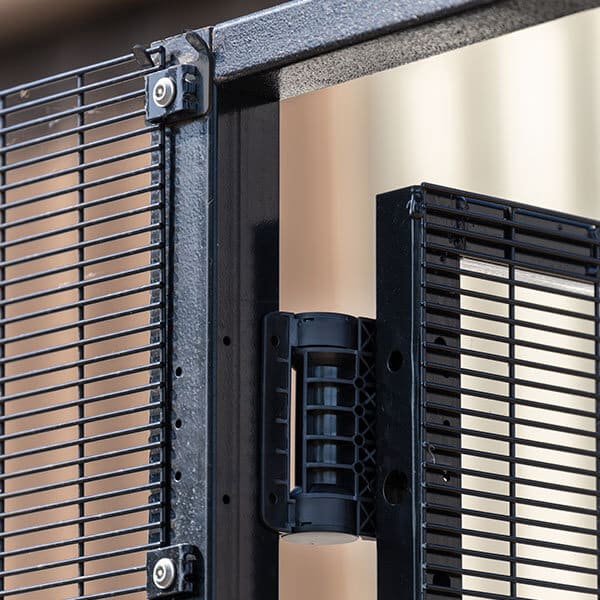

- Hooked Clip Inserts: Mesh panels hang freely from each post during setup

- Anti-Tamper Fixings: All panel clips secured with steel anti-tamper bolts

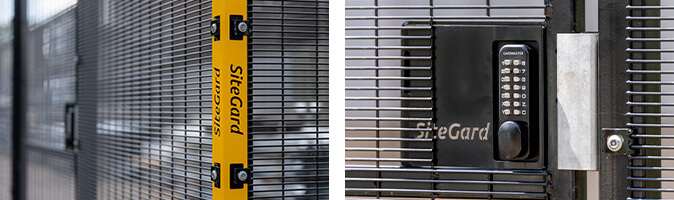

- High-Visibility Corners: Yellow corner protectors improve safety awareness and hide mesh ends

- Reusable Structure: Ideal for multi-phase or multi-site use

Secure Access Control, Configured for Your Site

CraneGard offers flexible tower crane access control with either a spacious 5.1m square layout or a more compact 2.6m wide compound. Both versions of the enclosure include:

- Inward or outward-opening gate options

- Lockable access (key or digital keypad)

- Internal push-pad for quick emergency access

- Optional 2.4m or 3m heights

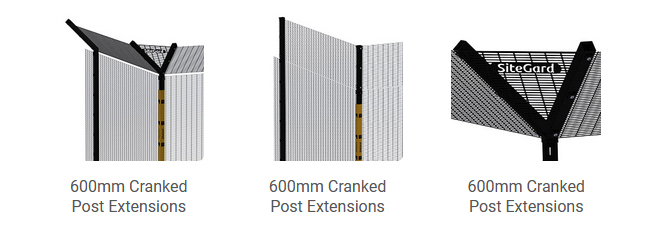

- Available with additional 600mm cranked or straight post extensions for enhanced anti-climb capability

In Stock and Ready for Delivery – Nationwide

We maintain stock of CraneGard tower crane surrounds and compatible SiteGard gates at our Kent depot. Same-day collection is available, and delivery can be arranged nationwide within 48 hours.

Whether you’re securing a high-rise project in London or a remote site elsewhere in the UK, our team can help you implement a reliable, compliant, and reusable tower crane protection system.

Get in Touch for Expert Tower Crane Safety Solutions

Secure your crane, protect your team, and meet your site’s safety obligations with CraneGard from SiteGard. Contact us today to discuss your project requirements, request a quote, or arrange a delivery.