Published:

Road crash barriers are essential safety installations designed to protect vehicles and passengers by minimising the impact of collisions.

These barriers are strategically placed along highways, roads, and other transportation infrastructures to manage traffic flow, enhance road safety, and reduce the risk of vehicles veering off the road.

Road crash barriers are usually made from either steel, concrete, or water-filled plastic. Each material serves different purposes and offers distinct advantages and disadvantages over the others. Let’s explore this further.

Water-Filled Plastic Crash Barriers

Water-filled plastic crash barriers are primarily used as temporary safety solutions. These barriers are constructed from durable plastic and designed to be filled with water on-site. The water they’re filled with acts like a cushion, absorbing the impact energy of the vehicle. This reduces the force of collisions and minimises damage to vehicles and injuries to passengers.

These road safety barriers are best suited for temporary needs in spaces like construction sites, roadworks, and event spaces. They are easy to transport and install, making them ideal for short-term deployments. They can also be quickly drained and moved to a new location, making these plastic barrier options very useful for temporary needs.

That said, water-filled barriers are not suitable for high-impact scenarios or permanent installations. Their primary limitation is their lower resistance to strong impacts compared to more robust materials like concrete or steel. They may also require frequent maintenance to ensure they remain filled and properly positioned.

Concrete Crash Barriers

Concrete crash barriers are a common sight on highways and major roads. These traffic barriers, known for their strength and durability, work by providing a solid, immovable object that can redirect vehicles back onto the roadway during a collision. Their weight and solid construction means they can withstand significant impacts without moving or deforming, making them a reliable choice for high-traffic areas.

These traffic barriers are ideal for permanent installations along highways, bridges, and median dividers where strong impact resistance is crucial. Once installed, they offer long-term durability and require minimal maintenance.

Due to their weight and the complexity of their installation, concrete barriers aren’t suitable for temporary or easily reconfigurable applications. They are also less flexible in terms of positioning, and require more time and resources to install and remove. So, while these safety barriers are fantastic for traffic management, protecting pedestrians and minimising the damage of collisions, they’re not ideal as temporary barriers.

Steel Crash Barriers

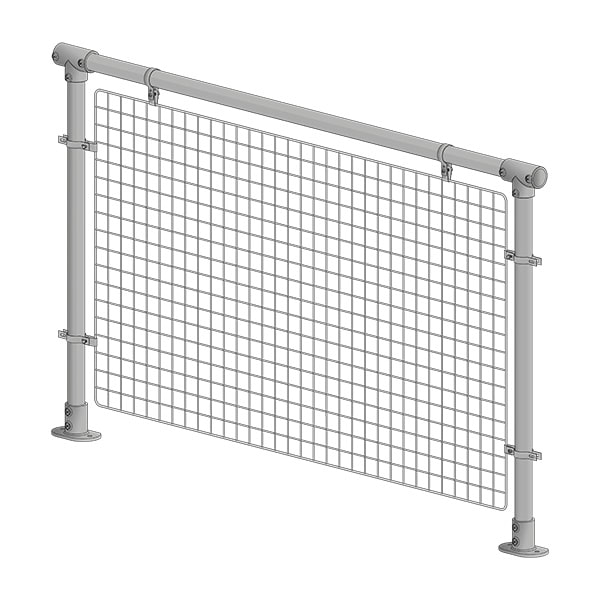

Steel crash barriers, such as the Armco Steel Crash Barriers, are widely used for their balance of strength, flexibility, and ease of installation. This type of safety barrier works by absorbing and redistributing the kinetic energy from a collision. Their W-beam design has a certain degree of flexibility, which allows them to bend slightly upon impact, reducing the force transmitted to the vehicle and its occupants.

Steel pedestrian barriers are versatile and can be used in both permanent and temporary settings. They are commonly found along highways, road curves, and at hazardous locations like construction sites, where they are used as site safety barriers.

Steel barriers are easier to install and repair compared to concrete barriers. However, while steel barriers are strong, they may not provide the same level of impact resistance as concrete barriers in extremely high-speed collisions. They can also be prone to corrosion over time if not properly maintained, especially in harsh weather conditions. At Alexandra Security, we mitigate these issues by galvanising and powder-coating our barriers, which have a maintenance-free life of over a decade, and up to 30 years.

Is Aluminium Used for Crash Barriers?

While aluminium is used for temporary, traffic control-type barriers because it’s light and easy to move around, this material is generally not used for road crash barriers, which must be designed to mitigate damage from high-impact collisions. This is due to:

- Strength: Aluminium is not as strong as steel and is less capable of withstanding high-impact collisions.

- Cost: Aluminium is generally more expensive than steel. Given the large quantities required for road barriers, the cost of aluminium barriers can really add up!

- Durability: While aluminium is flexible, it tends to have lower tensile strength and can suffer from fatigue over time, potentially leading to failures under repeated stress.